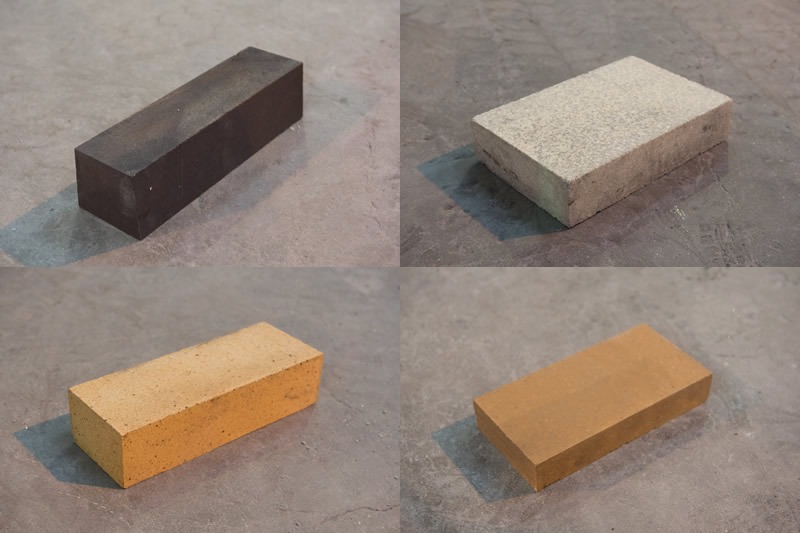

Refractory Bricks In The Spotlight

5

We can supply any type of brick to a specific size to your needs, we keep a stock of standard sizes at our facility in Scunthorpe also.

Basic Magnesite bricks are one of the most widely used basic refractory bricks, we can help you choose the right brick for your application. Alumina bricks are great for performing at high temperatures and have excellent corrosion and wear resistance, a high bulk density and low iron content. Call our sales team for the best price and availability for your refractory bricks.

Fired Magnesia - These bricks fired at high temperatures are volume stable in use. They show good corrosion & chemical resistance and can be fired at various temperatures.

Magnesia Carbon - Magnesia Carbon bricks are produced with non-fired basic refractory material. Resin bonded. Improves corrosion and slag resistance whilst adding graphite. They have excellent corrosion resistance together with good thermal shock properties. These bricks are widely used in EAF’s Ladles and relining furnaces.

Magnesia Chrome - Magnesia Chrome bricks are made from high purity magnesia and chrome. The bricks perform well at high temperatures and have good thermal stability. Magnesia chrome bricks are mostly commonly used in cement kilns and non-ferrous furnaces.

Alumina Bricks - Great for performing at high temperatures and have excellent corrosion and wear resistance, a high bulk density and low iron content. They are used in all kinds of industrial furnaces and high temperature applications to improve furnace lives. We can provide fire bricks with varying levels of Alumina content from 40% up to 90%.

Other Articles

UK Manufacturers Face New Costs & Compliance As The Carbon Border Tax Comes Into Force

20

Season's Greetings From Trent Refractories

15

Driving Sustainability Through Innovation

04

Ceramics UK Highlighting The Strategic Importance Of Refractories

01

Trent Refractories Attend The IRE UK Conference 2025

19

Trent Refractories Represented At UNITECR 2025 In Mexico

03

Trent Refractories Attending UNITECR 2025 In Mexico

16

Shaped Products In The Spotlight With Trent Refractories

06

Women At Refractories Fired Up Interview With Katy Moss

22

What A Fantastic Time At The ICR 2025 Aachen Conference

19