VIM Stick Casting Trial

10

Innovation within our industry sector continues at a rapid rate with new technologies, processes and standards advancing each year. Trent Refractories are starting the year with a case study that demonstrates innovation at the highest levels. Our client has an established process manufacturing large diameter, nickel super-alloy ingots using a Vacuum Induction Melting (VIM) process.

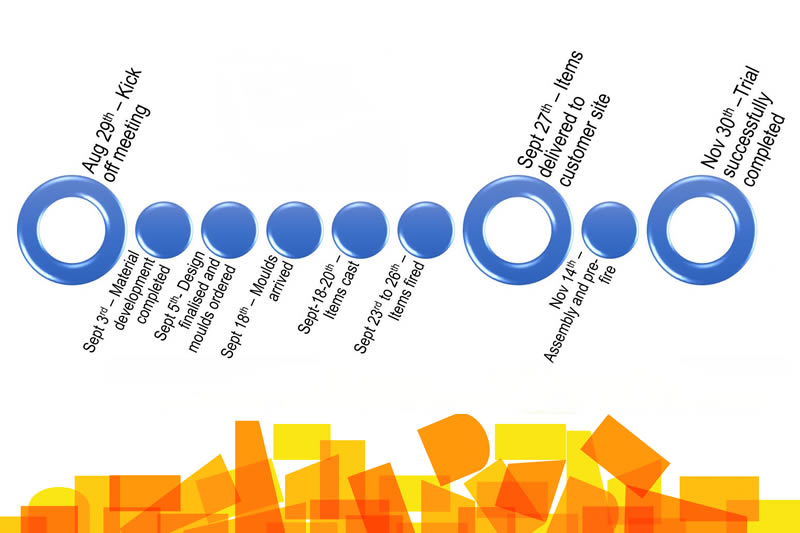

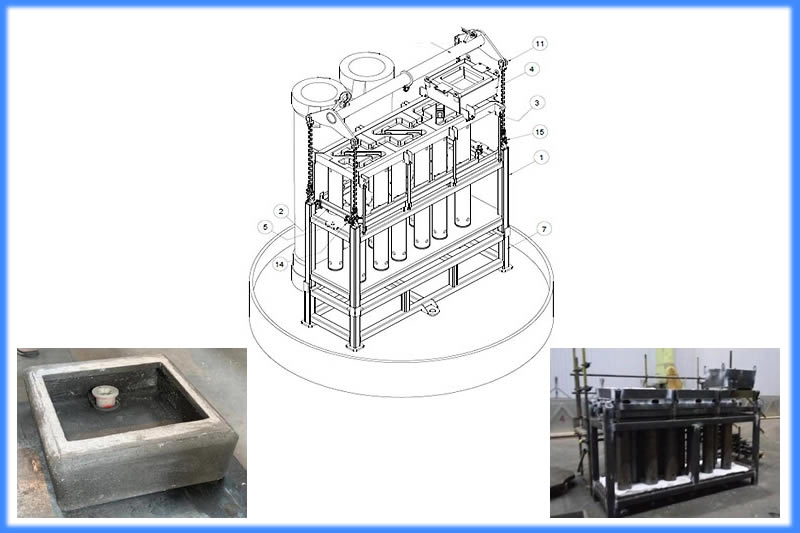

Trent Refractories were invited to participate in a feasibility study investigating manufacture of smaller, diameter sticks by supplying a proto-type catcher box. The project required material development, engineering, design, mould fabrication and external firing to 1000°C. The timescales for delivery were set at three weeks and the collective team delivered the solution allowing for a trial period which was viewed as a success by the client. Refractories innovation at its finest.

Other Articles

UK Manufacturers Face New Costs & Compliance As The Carbon Border Tax Comes Into Force

20

Season's Greetings From Trent Refractories

15

Driving Sustainability Through Innovation

04

Ceramics UK Highlighting The Strategic Importance Of Refractories

01

Trent Refractories Attend The IRE UK Conference 2025

19

Trent Refractories Represented At UNITECR 2025 In Mexico

03

Trent Refractories Attending UNITECR 2025 In Mexico

16

Shaped Products In The Spotlight With Trent Refractories

06

Women At Refractories Fired Up Interview With Katy Moss

22

What A Fantastic Time At The ICR 2025 Aachen Conference

19